Fiber optic cable is a cable containing one or multiple optical fibers that are used to transmit the signal. The optical fiber elements are typically individually coated with layers and contained in a protective tube suitable for the environment where the cable will be deployed.

Starting custom your ideal cable size by E-mail: trade@huadongcablegroup.com

Starting custom your ideal cable size by E-mail: trade@huadongcablegroup.com

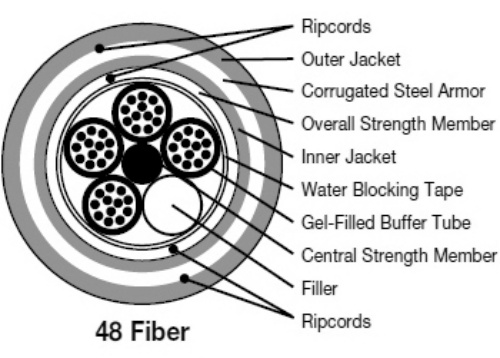

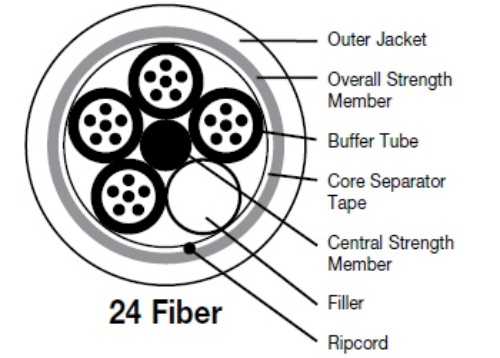

24 and 48 core optic fiber cable parameter:

| Fiber count | No.oflosse Tubes | No.OV Fillers | Nominal Cable | Nominal Cable | Maximum Tensile Load | |||||

| Diamieter | Weight | In stallation | In-service | |||||||

| IN | mm | LBS/1000′ | kg/km | LBS | N | LBS | N | |||

| 48 | 4 | 1 | 0.591 | 15 | 128 | 190 | 600 | 2670 | 180 | 800 |

| 48 | 4 | 1 | 0.476 | 12.1 | 91 | 135 | 600 | 2670 | 180 | 800 |

| 24 | 2 | 3 | 0.591 | 15 | 128 | 190 | 600 | 2670 | 180 | 800 |

| 24 | 2 | 3 | 0.476 | 12.1 | 91 | 135 | 600 | 2670 | 180 | 800 |

- * Fiber:

- ▪ 12core,24core,36core,48core, 72core,96core

- ▪ Loose tube gel-filled

- ▪ -coding per TIA/EIA 598B

- * Central Strength Member:

- ▪ Epoxy/glass rod

- * Inner Jacket:

- ▪ Black UV-and moisture-resistant polyethylene (PE)

- * Armor:

- ▪ 0.006″ corrugated coated steel tape

- * Outer Jacket:

- ▪ Black UV- and moisture-resistant polyethylene (PE)

- ▪ Sequential footage markings

- * Features:

- ▪ Loose tube gel-filled construction for superior fiber protection

- ▪ UV- and moisture-resistant design

- ▪ Rodent-resistant construction

- ▪ Dry Water Block cable core for ease of handling

- * Applications:

- ▪ Interbuilding voice or data communication backbones

- ▪ Installed in ducts, underground conduits, aerial/lashed or direct buried

- * Compliances:

- ▪ ANSI/TIA/EIA 568B.3

- ▪ ICEA S-87-640

- ▪ Rural Utilities Service (RUS) 7 CFR 1755.900 (REA PE-90)

- ▪ GR-20 Verified

- ▪ RoHS Compliant Directive 2002/95/EC

- * Options:

- ▪ Alternate 6-fiber per tube available upon request

- ▪ Sequential meter markings available upon request

- * Temperature:

- ▪ Storage -40°C (-40°F) to +75°C (+167°F)

- ▪ Operating -40°C (-40°F) to +70°C (+158°F)

- * Minimum Bend Radius:

- ▪ 20 X OD—Installation

- ▪ 10 X OD—In-Service

- * Maximum Crush Resistance:

- ▪ lbs/in (220 N/cm)

| Singie Layer Central Tube Optical Ground Wire (OPGW) | |||||

| Specification | Fiber Count | Diameter (mm) | Weight(kg/km) | RTS (KN) | Short Circuit Capacity(KA2s) |

| OPGW-32(40.6:4.7) | 12 | 78 | 243 | 40.6 | 47 |

| OPGW-42(54.0:8.4) | 24 | 9 | 313 | 54 | 8.4 |

| OPGW-42(43.5:10.6) | 24 | 9 | 284 | 43.5 | 10.6 |

| OPGW-54(55.9:17.5) | 36 | 10.2 | 394 | 67.8 | 13.9 |

| OPGW-61(73.7:175) | 48 | 10.8 | 438 | 73.7 | 17.5 |

| OPGW-61(55.1:24.5) | 48 | 10.8 | 358 | 55.1 | 24.5 |

| OPGW-68(80.8:21.7) | 54 | 11.4 | 485 | 80.8 | 21.7 |

| OPGW-75(54.5:41.7) | 60 | 12 | 459 | 63 | 36.3 |

| OPGW-76(54.5:41.7) | 60 | 12 | 385 | 545 | 41.7 |

| Double Layer Central Tube Optical Ground Wire (OPGw) | |||||

| Specification | Fiber Count | Diameter (mm) | Weight(kg/km) | RTS(KN) | Short Circuit Capacity(KA2s) |

| OPGW-96[1217;42.2] | 12 | 13 | 671 | 121.7 | 42.2 |

| OPGW-127[141.0:87.9] | 3 | 15 | 825 | 141 | 87.9 |

| OPGW-127[77.8.128.0] | 3 | 15 | 547 | 77.8 | 128 |

| OPGW-145(121.0.132.2) | 28 | 16 | 857 | 121 | 132.2 |

| OPGW-163(138 2.183.6) | 36 | 17 | 910 | 138.2 | 186.3 |

| OPGW-163(99.9.213.7) | 36 | 17 | 694 | 99.9 | 213.7 |