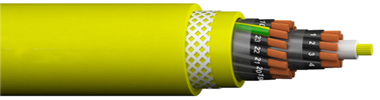

H-3PNCT 3,3KV and 6,6KV for Reel system (Traveling)

- Voltage: AC 3300V, AC 6600V

- Conductor: Class 5 flexible tinned copper wires

- Screen: Semi-conductive screen

- Insulation: EPR compound

- Shield braid: Tinned copper braiding screen with aramid fiber reinforcement

- Outer sheath: Chloroprene rubber

- Temperature Rating: -20°C to +90°C

- Feature: High resistance to lateral pressure and bending

- Application: Reel system (Traveling)

FG-H-3PNCT 3,3KV and 6,6KV for Reel system (Traveling)

- Voltage: AC 3300V, AC 6600V

- Conductor: Copper /Tinned annealed copper

- Inner Screen: Semi-conductive screen

- Insulation: EPR compound

- Outer Screen: Semi-conductive screen

- Shield braid: Tinned copper braiding screen with aramid fiber reinforcement

- Optical fiber cord

- Outer sheath: Sheath PCP (Polychloroprene) Type EM2

- Rated Temperature: 80 degrees C

- Feature: High resistance to lateral pressure and bending

- Application: Reel system (Traveling)

FG-RE-3PNCT 6,6KV for Reel system (Traveling)

- Voltage: AC 6600V

- Test Voltage: 17000V / 10 minutes

- Conductor: Copper /Tinned annealed copper

- Insulation: EPR compound

- Outer sheath: Chloroprene rubber

- Rated Temperature: 80 degrees C

- Feature: High resistance to lateral pressure and bending

- Application: Reel system (Traveling)

- 3300V H-3PNCT

- 3300V FG-H-3PNCT

- 6600V FG-RE-3PNCT

| No. of Cores | Conductor | Insulation Thickness(mm) | Approx. Mass(kg/km) | ||

| Size(mm2) | Construction(No./mm) | Outer Diameter (mm) | |||

| 3 | 22 | 7/20/0.45 | 7.0 | 3.0 | 2,340 |

| 38 | 7/34/0.45 | 9.1 | 3.0 | 3,190 | |

| 60 | 19/20/0.45 | 11.6 | 3.5 | 4,500 | |

| 100 | 19/34/0.45 | 15.2 | 3.5 | 6,320 | |

| 4 | 22 | 7/20/0.45 | 7.0 | 3.0 | 3,150 |

| 38 | 7/34/0.45 | 9.1 | 3.0 | 4,300 | |

| 60 | 19/20/0.45 | 11.6 | 3.5 | 6,080 | |

| 100 | 19/34/0.45 | 15.2 | 3.5 | 8,600 | |

| No. of Cores | Conductor | Insulation Thickness(mm) | Approx. Mass(kg/km) | ||

| Size(mm2) | Construction(No./mm) | Outer Diameter (mm) | |||

| 3×38 + 1×22 + 6 optical fiber cores | 38 | 7/34/0.45 | 9.1 | 3.0 | 4,530 |

| 22 | 7/20/0.45 | 7.0 | 1.6 | ||

| 3×50 + 1×30 + 6 optical fiber cores | 50 | 19/16/0.45 | 10.4 | 3.5 | 5,510 |

| 30 | 7/27/0.45 | 8.1 | 1.6 | ||

| 3×60 + 1×30 + 6 optical fiber cores | 60 | 19/20/0.45 | 11.6 | 3.5 | 6,140 |

| 30 | 7/27/0.45 | 8.1 | 1.6 | ||

| No. of Cores | Conductor | Insulation Thickness(mm) | Approx. Mass(kg/km) | ||

| Size(mm2) | Construction(No./mm) | Outer Diameter (mm) | |||

| 3×38 + 1×22 + 6 optical fiber cores | 38 | 7/34/0.45 | 9.1 | 3.0 | 4,390 |

| 22 | 7/20/0.45 | 7.0 | 1.6 | ||

| 3×50 + 1×30 + 6 optical fiber cores | 50 | 19/16/0.45 | 10.4 | 3.5 | 5,070 |

| 30 | 7/27/0.45 | 8.1 | 1.6 | ||

| 3×60 + 1×30 + 6 optical fiber cores | 60 | 19/20/0.45 | 11.6 | 3.5 | 5,640 |

| 30 | 7/27/0.45 | 8.1 | 1.6 | ||

CUR-2PNCT/CUR-2PNCT-SB (Festoon)

- Voltage: 600V

- Test Voltage: 3000V /1 minute

- Conductor: Copper /Tinned annealed copper

- Insulation: EPR compound

- Shield braid: Copper wire/Tinned Copper wire

- Outer sheath: Chloroprene rubber

- Rated Temperature: 80 degrees C

- Feature: High flexibility

- Application: Festoon System and Lift System

CUR-3PNCT/CUR-3PNCT-SB (Festoon)

- Voltage: 600V

- Test Voltage: 3000V /1 minute

- Conductor: Copper /Tinned annealed copper

- Insulation: EPR compound

- Shield braid: Copper wire/Tinned Copper wire

- Outer sheath: Chloroprene rubber

- Reinforcement: Embedded yarn braid

- Rated Temperature: 80 degrees C

- Feature: High flexibility and impact resistance

- Application: Festoon System and Lift System

Flat Type SK-2PNCT for Festoon System

- Voltage: 600V

- Test Voltage: 3000V /1 minute

- Conductor: Copper /Tinned annealed copper

- Insulation: EPR compound

- Shield braid: Copper wire/Tinned Copper wire

- Outer sheath: Chloroprene rubber

- Reinforcement: Embedded yarn braid

- Rated Temperature: 80 degrees C

- Feature: High flexibility

- Application: Festoon System and Lift System

- 600V CUR-2PNCT Cable Parameter

- 600V CUR-3PNCT Cable Parameter

- Flat SK-2PNCT Cable Parmater

| No. of Cores | Conductor | Insulation Thickness (mm) | Sheath Thickness (mm) | Approx. Overall Diameter (mm) | Approx. Mass (kg/km) | ||

| Size (mm2) | Construction (No./mm) | Outer Diameter (mm) | |||||

| 12 | 0.75 | 30/0.18 | 1.1 | 0.8 | 2.1 | 17 | 335 |

| 1.25 | 50/0.18 | 1.5 | 0.8 | 2.2 | 18.5 | 440 | |

| 2 | 37/0.26 | 1.8 | 0.8 | 2.3 | 20 | 560 | |

| 3.5 | 45/0.32 | 2.5 | 0.8 | 2.5 | 24 | 845 | |

| 16 | 0.75 | 30/0.18 | 1.1 | 0.8 | 2.2 | 18.5 | 415 |

| 1.25 | 50/0.18 | 1.5 | 0.8 | 2.3 | 21 | 550 | |

| 2 | 37/0.26 | 1.8 | 0.8 | 2.4 | 22 | 705 | |

| 3.5 | 45/0.32 | 2.5 | 0.8 | 2.7 | 26 | 1080 | |

| 20 | 1.25 | 50/0.18 | 1.5 | 0.8 | 2.5 | 23 | 680 |

| 2 | 37/0.26 | 1.8 | 0.8 | 2.6 | 25 | 870 | |

| 24 | 1.25 | 50/0.18 | 1.5 | 0.8 | 2.6 | 25 | 810 |

| 2 | 37/0.26 | 1.8 | 0.8 | 2.7 | 27 | 1050 | |

| 3.5 | 45/0.32 | 2.5 | 0.8 | 3 | 32 | 1610 | |

| No. of Cores | Conductor | Insulation Thickness (mm) | Thickness of Reinforcement (mm) | Sheath Thickness (mm) | Approx. Overall Diameter (mm) | Approx. Mass (kg/km) | ||

| Size (mm2) | Construction (No./mm) | Outer Diameter (mm) | ||||||

| 5 | 2 | 37/0.26 | 1.8 | 1.2 | 0.5 | 3 | 18.5 | 420 |

| 3.5 | 45/0.32 | 2.5 | 1.2 | 0.5 | 3.1 | 21 | 565 | |

| 5.5 | 70/0.32 | 3.1 | 1.2 | 0.5 | 3.2 | 23 | 720 | |

| 10 | 2 | 37/0.26 | 1.8 | 1.2 | 1 | 3.4 | 27 | 790 |

| 3.5 | 45/0.32 | 2.5 | 1.2 | 1 | 3.6 | 30 | 1080 | |

| 12 | 2 | 37/0.26 | 1.8 | 1.2 | 1 | 3.4 | 28 | 870 |

| 3.5 | 45/0.32 | 2.5 | 1.2 | 1 | 3.7 | 32 | 1230 | |

| 16 | 2 | 37/0.26 | 1.8 | 1.2 | 1 | 3.6 | 30 | 1080 |

| 3.5 | 45/0.32 | 2.5 | 1.2 | 1 | 3.8 | 34 | 1520 | |

| 20 | 2 | 37/0.26 | 1.8 | 1.2 | 1 | 3.8 | 34 | 1330 |

| 3.5 | 45/0.32 | 2.5 | 1.2 | 1 | 4 | 38 | 1850 | |

| 24 | 2 | 37/0.26 | 1.8 | 1.2 | 1 | 3.9 | 36 | 1560 |

| 3.5 | 45/0.32 | 2.5 | 1.2 | 1 | 4.2 | 41 | 2200 | |

| 30 | 2 | 37/0.26 | 1.8 | 1.2 | 1 | 4.1 | 39 | 1850 |

| 3.5 | 45/0.32 | 2.5 | 1.2 | 1 | 4.4 | 44 | 2620 | |

| No. of Cores | Conductor | Insulation Thickness (mm) | Sheath Thickness (mm) | Approx. Overall Diameter (mm) | Approx. Mass (kg/km) | ||

| Size (mm2) | Construction (No./mm) | Outer Diameter (mm) | |||||

| 3 | 22 | 7/20/0.45 | 7 | 1.2 | 2.6 | 15.5X35 | 1160 |

| 38 | 7/34/0.45 | 9.1 | 1.2 | 2.9 | 18.0X42 | 1750 | |

| 60 | 19/20/0.45 | 11.6 | 1.5 | 3.3 | 22X52 | 2700 | |

| 100 | 19/34/0.45 | 15.2 | 2 | 3.9 | 28X66 | 4460 | |

| 24 | 1.25 | 50/0.18 | 1.5 | 0.8 | 2.9 | 18.0X42 | 1230 |

| 32 | 1.25 | 50/0.18 | 1.5 | 0.8 | 3.3 | 19.0X55 | 1540 |

| 40 | 1.25 | 50/0.18 | 1.5 | 0.8 | 3.7 | 19.5X68 | 1980 |

| 48 | 1.25 | 50/0.18 | 1.5 | 0.8 | 2.9 | 18.0X84 | 2260 |

| 56 | 1.25 | 50/0.18 | 1.5 | 0.8 | 2.9 | 18.0X102 | 2730 |

| 64 | 1.25 | 50/0.18 | 1.5 | 0.8 | 3.3 | 19.0X109 | 3080 |

| 72 | 1.25 | 50/0.18 | 1.5 | 0.8 | 2.9 | 18.0X126 | 3390 |

| 80 | 1.25 | 50/0.18 | 1.5 | 0.8 | 3.7 | 19.5X135 | 3950 |

RE-2PNCT/RE-3PNCT for Reeling System

- Voltage: 600V

- Test Voltage: 3000V / 1 minute

- Conductor: Copper / Tinned annealed copper

- Insulation: EPR compound

- Shield braid: Copper wire/Tinned Copper wire

- Reinforcement: Embedded yarn braid

- Outer sheath: Chloroprene rubber

- Core identification: Color coding / tracer method

- Feature: High resistance to lateral pressure and bending

- Application: Suitable for the reel systems (manually wound) for crane travel

RE(V)-2PNCT-FR for Vertical Reeling

- Voltage: 600V

- Test Voltage: 3000V /1 minute

- Conductor: Copper /Tinned annealed copper

- Insulation: EPR compound

- Shield braid: Copper wire/Tinned Copper wire

- Reinforcement: Embedded yarn braid

- Outer sheath: Chloroprene rubber

- Core identification: Color coding/tracer method

- Feature: High resistance to lateral pressure and bending

- Application: Vertical reel system used in landfills, etc.

Flat 2PNCT/3PNCT (Reeling System)

- Voltage: 600V

- Conductor: Copper /Tinned annealed copper

- Insulation: EPR compound

- Shield braid: Copper wire/Tinned Copper wire

- Outer sheath: Chloroprene rubber

- Core identification: For power or control core unit

- 3-core (black, white, and red)

- 4-core (black, white, red, and green)

- Control cores

- Feature: High resistance to lateral pressure and bending

- Application: Reel system (Traveling).

- RE-3PNCT Cable Parameter

- RE(V)-2PNCT-FR Cable Parameter

- Flat H-3PNCT Cable Parmater

| No. of Cores | Conductor | Insulation Thickness (mm) | Thickness of Reinforcement (mm) | Sheath Thickness (mm) | Approx. Overall Diameter (mm) | Approx. Mass (kg/km) | ||

| Size (mm2) | Construction (No./mm) | Outer Diameter (mm) | ||||||

| 3 | 14 | 88/0.45TA | 4.9 | 1.2 | 1 | 3.3 | 26 | 940 |

| 22 | 7/20/0.45TA | 7 | 1.6 | 1 | 3.7 | 32 | 1490 | |

| 30 | 7/27/0.45TA | 8.1 | 1.6 | 1 | 3.9 | 35 | 1830 | |

| 4 | 38 | 7/34/0.45TA | 9.1 | 1.6 | 1 | 4.2 | 40 | 2720 |

| 6 | 3.5 | 3/0.32TST+45/0.32TA | 2.6 | 1.2 | 0.5 | 3.2 | 24 | 730 |

| 8 | 3/0.32TST+50/0.45TA | 3.8 | 1.2 | 0.5 | 3.5 | 28 | 1180 | |

| 10 | 3.5 | 3/0.32TST+45/0.32TA | 2.6 | 1.2 | 1 | 3.7 | 32 | 1190 |

| 12 | 3.5 | 3/0.32TST+45/0.32TA | 2.6 | 1.2 | 1 | 3.7 | 33 | 1320 |

| 16 | 3.5 | 3/0.32TST+45/0.32TA | 2.6 | 1.2 | 1 | 3.9 | 36 | 1650 |

| 20 | 3.5 | 3/0.32TST+45/0.32TA | 2.6 | 1.2 | 1 | 4.1 | 40 | 2000 |

| 24 | 3.5 | 3/0.32TST+45/0.32TA | 2.6 | 1.2 | 1 | 4.4 | 44 | 2400 |

| 30 | 3.5 | 3/0.32TST+45/0.32TA | 2.6 | 1.2 | 1 | 4.5 | 46 | 2830 |

| No. of Cores | Conductor | Insulation Thickness (mm) | Thickness of Reinforcement (mm) | Sheath Thickness (mm) | Approx. Overall Diameter (mm) | Approx. Mass (kg/km) | ||

| Size (mm2) | Construction (No./mm) | Outer Diameter (mm) | ||||||

| 7 | 3.5 | 3/0.32TST+45/0.32TA | 2.6 | 0.8 | 0.5 | 3.1 | 22 | 670 |

| 5.5 | 3/0.32TST+70/0.32TA | 3.2 | 1 | 0.5 | 3.4 | 26 | 990 | |

| 10 | 3.5 | 3/0.32TST+45/0.32TA | 2.6 | 0.8 | 1 | 3.4 | 27 | 1010 |

| 5.5 | 3/0.32TST+70/0.32TA | 3.2 | 1 | 1 | 3.7 | 32 | 1480 | |

| 13 | 3.5 | 3/0.32TST+45/0.32TA | 2.6 | 0.8 | 1 | 3.7 | 32 | 1370 |

| 5.5 | 3/0.32TST+70/0.32TA | 3.2 | 1 | 1 | 4 | 38 | 2020 | |

| No. of Cores | Conductor | Insulation Thickness (mm) | Thickness of Reinforecement (mm) | Sheath Thickness (mm) | Approx. Overall Diameter (mm) | Approx. Mass (kg/km) | Max. Conductor Resistance | ||

| Size (mm2) | Construction (No./mm) | Outer Diameter (mm) | |||||||

| 3 | 22 | 7/20/0.45 | 7 | 1.6 | 1 | 3.6 | 20X49 | 1640 | 0.892 |

| 30 | 7/27/0.45 | 8.1 | 1.6 | 1 | 3.7 | 21X52 | 1960 | 0.661 | |

| 38 | 7/34/0.45 | 9.1 | 1.6 | 1 | 3.8 | 22X55 | 2290 | 0.525 | |

| 50 | 19/16/0.45 | 10.4 | 2.1 | 1 | 4.2 | 26X63 | 2970 | 0.411 | |

| 60 | 19/20/0.45 | 11.6 | 2.1 | 1 | 4.3 | 27X66 | 3440 | 0.329 | |

| 80 | 19/27/0.45 | 13.5 | 2.1 | 1 | 4.5 | 29X72 | 4290 | 0.243 | |

| 100 | 19/34/0.45 | 15.2 | 2.1 | 1 | 4.7 | 31X77 | 5100 | 0.193 | |

| 125 | 19/42/0.45 | 16.9 | 2.7 | 1 | 5.1 | 35X86 | 6360 | 0.156 | |

| 150 | 27/34/0.45 | 18.7 | 2.7 | 1 | 5.3 | 36X90 | 7110 | 0.136 | |

| 200 | 37/34/0.45 | 21.2 | 3.3 | 1 | 5.8 | 41X104 | 9590 | 0.0993 | |

| 250 | 37/42/0.45 | 23.6 | 3.3 | 1 | 6.2 | 45X113 | 11500 | 0.0803 | |

CAR-2PNCT/CAR-3PNCT (Carrier Drum)

- Voltage: 600V

- Test Voltage: 3000V /1 minute

- Conductor: Copper /Tinned annealed copper

- Insulation: EPR compound

- Shield braid: Copper wire/Tinned Copper wire

- Reinforcement: Embedded yarn braid

- Outer sheath: Chloroprene rubber

- Core identification: Color coding/tracer method

- Feature: Lateral pressure resistance

- Application: Traversing carrier roller system of overhead cranes and cable chain system.

TOR-2PNCT Cable (Torsion System)

- Voltage: 600V

- Test Voltage: 3000V /1 minute

- Conductor: Copper /Tinned annealed copper

- Insulation: EPR compound

- Shield braid: Copper wire/Tinned Copper wire

- Outer sheath: Chloroprene rubber

- Core identification: Color coding/tracer method

- Feature: High torsion resistance

- Application: Suitable to the revolving parts of rotary cranes.

- Standards: JIS C 3327 or other international standards

SPD-FHNCT for Spreader Basket

- Voltage: 600V

- Test Voltage: 3000V /1 minute

- Conductor: Copper /Tinned annealed copper

- Insulation: ETFE insulation

- Outer sheath: Chloroprene rubber

- Core identification: Color coding/tracer method

- Feature: Stable collecting performance into the basket, and high lateral pressure resistance

- Application: Suitable for gravity collector basket system of the container crane at harbors (for Quayside cranes).

- Standards: JIS or other international standards

- CAR-2PNCT Cable Parameter

- Tor-2PNCT Cable Parameter

- SPD-FHNCT/SPD (Y)-2PNCT Cable Parameter

| No. of Cores | Conductor | Insulation Thickness (mm) | Sheath Thickness (mm) | Approx. Overall Diameter (mm) | Approx. Mass (kg/km) | ||

| Size (mm2) | Construction (No./mm) | Outer Diameter (mm) | |||||

| 3 | 8 | 50/0.45 | 3.7 | 1 | 2.1 | 17 | 475 |

| 14 | 88/0.45 | 4.9 | 1 | 2.3 | 20 | 730 | |

| 22 | 7/20/0.45 | 7 | 1.2 | 2.7 | 26 | 1180 | |

| 4 | 38 | 7/34/0.45 | 9.1 | 1.2 | 3.2 | 34 | 2280 |

| 6 | 3.5 | 45/0.32 | 2.5 | 0.8 | 2.1 | 17 | 465 |

| 8 | 50/0.45 | 3.7 | 1 | 2.4 | 22 | 890 | |

| 10 | 3.5 | 45/0.32 | 2.5 | 0.8 | 2.5 | 23 | 790 |

| 12 | 3.5 | 45/0.32 | 2.5 | 0.8 | 2.5 | 24 | 815 |

| 16 | 3.5 | 45/0.32 | 2.5 | 0.8 | 2.7 | 26 | 1080 |

| 20 | 3.5 | 45/0.32 | 2.5 | 0.8 | 2.8 | 29 | 1330 |

| 24 | 3.5 | 45/0.32 | 2.5 | 0.8 | 3 | 32 | 1630 |

| 30 | 3.5 | 45/0.32 | 2.5 | 0.8 | 3.2 | 36 | 2080 |

| No. of Cores | Conductor | Insulation Thickness (mm) | Sheath Thickness (mm) | Approx. Overall Diameter (mm) | Approx. Mass (kg/km) | ||

| Size (mm2) | Construction (No./mm) | Outer Diameter (mm) | |||||

| 14 | 88/0.45 | 4.9 | 1 | 2.3 | 20 | 725 | |

| 22 | 7/20/0.45 | 7 | 1.2 | 2.7 | 26 | 1170 | |

| 30 | 7/27/0.45 | 8.1 | 1.2 | 2.8 | 28 | 1460 | |

| 4 | 38 | 7/34/0.45 | 9.1 | 1.2 | 3.2 | 34 | 2280 |

| 6 | 3.5 | 45/0.32 | 2.5 | 0.8 | 2.1 | 17 | 460 |

| 8 | 50/0.45 | 3.7 | 1 | 2.4 | 22 | 875 | |

| 10 | 3.5 | 45/0.32 | 2.5 | 0.8 | 2.5 | 24 | 770 |

| 12 | 3.5 | 45/0.32 | 2.5 | 0.8 | 2.6 | 24 | 875 |

| 16 | 3.5 | 45/0.32 | 2.5 | 0.8 | 2.7 | 27 | 1110 |

| 20 | 3.5 | 45/0.32 | 2.5 | 0.8 | 2.9 | 30 | 1380 |

| 24 | 3.5 | 45/0.32 | 2.5 | 0.8 | 3.1 | 33 | 1660 |

| 30 | 3.5 | 45/0.32 | 2.5 | 0.8 | 3.2 | 35 | 1990 |

| 600V SPD-FHNCT | ||||||||

| No. of Cores | Conductor | Insulation Thickness (mm) | Sheath Thickness (mm) | Approx. Overall Diameter (mm) | Approx. Mass (kg/km) | Max. Conductor Resistance (20 degrees C) (Ω/km) | ||

| 30 | 3.5 | 45/0.32 | 2.5 | 0.4 | 6 | 42 | 2710 | 5.54 |

| 36 | 3.5 | 45/0.32 | 2.5 | 0.4 | 7 | 46 | 3090 | 5.54 |

| 42 | 3.5 | 45/0.32 | 2.5 | 0.4 | 7 | 50 | 3820 | 5.54 |

| 600V SPD (Y)-2PNCT | ||||||||

| No. of Cores | Conductor | Insulation Thickness (mm) | Sheath Thickness (mm) | Approx. Overall Diameter (mm) | Approx. Mass (kg/km) | Max. Conductor Resistance (20 degrees C) (Ω/km) | ||

| Size (mm2) | Construction (No./mm) | Outer Diameter (mm) | ||||||

| 30 | 3.5 | 3/0.32TST + 45/0.32TA | 2.6 | 0.8 | 3.3 | 37 | 2130 | 5.54 |

| 36 | 3.5 | 3/0.32TST + 45/0.32TA | 2.6 | 0.8 | 3.5 | 40 | 2520 | 5.54 |

| 42 | 3.5 | 3/0.32TST + 45/0.32TA | 2.6 | 0.8 | 3.7 | 43 | 2930 | 5.54 |

Crane cable application environment

Reeling Operation System

Festoon Operation System

Basket Operation System

Chain Operation System

Trailing Operation System