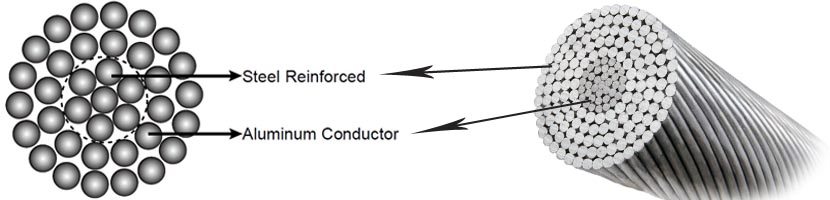

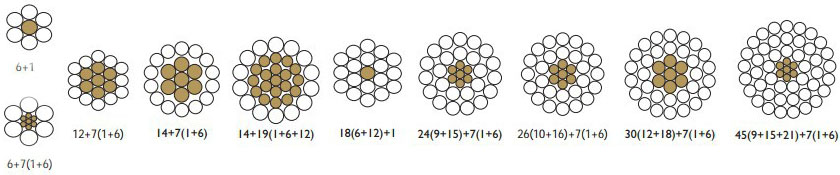

Construction: The mixed construction of ACSR makes it a very flexible medium from the design point of view. By varying the relative proportions of aluminium and steel, the ideal conductor for any particular application can be produced. Generally, ACSR consists of a galvanized steel core of 1 wire, 7 wires or 19 wires surrounded by concentric layers of aluminium wire. When a conductor with a high current carrying capacity and comparatively low strength is required, special construct.

Character: 1. Aluminum Conductor; 2. Steel Reinforced; 3. Bare.

Application: Used as bare overhead transmission conductor and as primary and secondary distribution conductor and messenger support. ACSR offers optimal strength for line design. Variable steel core stranding enables desired strength to be achieved without sacrificing ampacity.

BS215 Standard ACSR Conductor Technical Characteristics

| Code name | Nominal aluminum area | Stranding structure | Sectional area of aluminum | Total sectional area | Overall diameter | Total | Current Rating | |

| mm2 | Al. No. | St. No. | mm2 | mm2 | mm | kg/km | A | |

| Gopher | 25 | 6 | 1 | 26.24 | 30.62 | 7.08 | 106 | 126 |

| Weasel | 30 | 6 | 1 | 31.61 | 36.88 | 7.77 | 128 | 134 |

| Fox | 35 | 6 | 1 | 36.66 | 42.77 | 8.37 | 149 | 147 |

| Rabbit | 50 | 6 | 1 | 52.88 | 61.7 | 10.05 | 214 | 185 |

| Mink | 60 | 6 | 1 | 63.18 | 73.71 | 10.98 | 255 | 174 |

| Horse | 70 | 12 | 7 | 73.37 | 116.2 | 13.95 | 538 | 268 |

| Cat | 90 | 6 | 1 | 95.4 | 111.3 | 15.9 | 386 | 248 |

| Dog | 100 | 6 | 7 | 105 | 118.5 | 14.15 | 394 | 278 |

| Tiger | 125 | 30 | 7 | 131.1 | 161.7 | 16.52 | 602 | 323 |

| Dingo | 150 | 18 | 1 | 158.7 | 167.5 | 16.75 | 506 | 349 |

| Wolf | 150 | 30 | 7 | 158.1 | 194.9 | 18.13 | 726 | 355 |

| Lynx | 175 | 30 | 7 | 183.4 | 326.2 | 19.53 | 842 | 386 |

| Panther | 200 | 30 | 7 | 212.1 | 261.5 | 21 | 974 | 421 |

| Lion | 225 | 30 | 7 | 238.5 | 294.2 | 22.26 | 1095 | 448 |

| Bear | 250 | 30 | 7 | 264 | 325.6 | 23.45 | 1213 | 481 |

| Goat | 300 | 30 | 7 | 324.3 | 400 | 25.97 | 1489 | 542 |

| Sheep | 350 | 30 | 7 | 374.1 | 461.4 | 27.93 | 1718 | 592 |

| Antilope | 350 | 54 | 7 | 373.1 | 421.5 | 26.73 | 1411 | 588 |

| Bizon | 350 | 54 | 7 | 381.8 | 431.3 | 27 | 1444 | 595 |

| Deer | 400 | 30 | 7 | 429.3 | 529.5 | 28.89 | 1971 | 639 |

| Zebra | 400 | 54 | 7 | 428.9 | 484.5 | 28.62 | 1621 | 635 |

| Moose | 500 | 54 | 7 | 528.7 | 597.2 | 31.77 | 1999 | 763 |

IEC Standard ACSR Technical characteristics

| Code number | Area | Number of wires | Wire dia. | Diameter | Rated Strength | ||||

| Alum | Steel | Alum. | Steel | Core | Cond. | ||||

| mm2 | mm2 | Al | St | mm | mm | mm | mm | kN | |

| 16 | 16 | 2.67 | 6 | 1 | 1.84 | 1.84 | 1.84 | 5.53 | 6.45 |

| 25 | 25 | 4.17 | 6 | 1 | 2.30 | 2.30 | 2.30 | 6.91 | 9.71 |

| 40 | 40 | 6.67 | 6 | 1 | 2.91 | 2.91 | 2.91 | 8.74 | 15.33 |

| 63 | 63 | 10.50 | 6 | 1 | 3.66 | 3.66 | 3.66 | 11.00 | 22.37 |

| 100 | 100 | 16.70 | 6 | 1 | 4.61 | 4.61 | 4.61 | 13.80 | 35.50 |

| 125 | 125 | 20.40 | 26 | 7 | 2.47 | 1.92 | 5.77 | 15.70 | 48.54 |

| 160 | 160 | 26.10 | 26 | 7 | 2.80 | 6.53 | 6.53 | 17.70 | 61.34 |

| 200 | 200 | 32.60 | 26 | 1 | 3.13 | 7.30 | 7.30 | 19.80 | 74.69 |

| 315 | 315 | 51.30 | 26 | 7 | 3.93 | 9.16 | 9.16 | 24.90 | 114.02 |

| 400 | 400 | 51.90 | 54 | 7 | 3.07 | 9.21 | 9.21 | 27.60 | 130.30 |

| 450 | 450 | 58.30 | 54 | 7 | 3.26 | 9.77 | 9.77 | 29.30 | 146.58 |

| 500 | 500 | 64.80 | 54 | 7 | 3.43 | 10.30 | 10.30 | 30.90 | 162.87 |

| 560 | 560 | 70.90 | 54 | 19 | 3.63 | 10.90 | 10.90 | 32.70 | 182.52 |

| 630 | 630 | 79.80 | 54 | 19 | 3.85 | 11.60 | 11.60 | 34.70 | 202.94 |

| 710 | 710 | 89.90 | 54 | 19 | 4.09 | 12.30 | 12.30 | 36.80 | 228.71 |

| 800 | 800 | 66.70 | 84 | 7 | 3.48 | 10.40 | 10.40 | 38.30 | 214.67 |

| 900 | 900 | 38.90 | 72 | 7 | 3.99 | 7.98 | 7.98 | 39.90 | 193.78 |