Description

Crane cable is used to cover a range of specialist cables powering and controlling cranes, hoists, festoons, conveyors and gantries. Used across heavy industry including mining and marine, they must be robust and capable of handling both torsional and tensile stresses simultaneously. These mobile machines for lifting and handling are often manufactured with robust rubber outer sheathing to protect against constant reeling and movement as well as providing protection against oils and greases. Cables with Polyethylene (PUR) and PVC sheathing are also available.

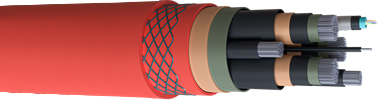

MV Flat EPR/PCP Reeling Cable-(N)TSFLCGEWOEU

- Voltage: 1.8/3kV, 3. 6/6kV, 6/10kV, 8. 7/15kV, 12/ 20 kV

- Conductor: Copper tinned, finely stranded, class F

- Insulation: EPR

- Electrical field control: Inner semi-conductive layer of EPR, outer semi conductive layer of modified NBR.

- Core arrangement: Three-core design, with earth conductor split into 3 parts positioned in the intersticess

- Sheath: EPR

- Anti-torsion braid: Reinforced braid made of polyester threads

- Outer Sheath: PCP

- Marking: (number of cores)x(cross-section) (rated voltage)

- Data transmission: A special cable design with fibre-optics can be customized

MV Round EPR/PCP Reeling Cable with Fiber Optic-TSKCGEWOEU

- Voltage: 3. 6/6kV, 6/10kV, 8. 7/15kV, 12/ 20 kV

- Conductor: Plain copper, fine stranded class 5

- Insulation: EPR

- Electrical field control: Inner and outer layer of semi-conductive rubber compound

- Optical Fiber: 12 fibers, 50/125µ or 62.5/125µ or E9/125µ, within protection jacket

- Core arrangement: Cores layed up around conductive filler with aramid rope in the center

- Inner Sheath: rubber (5GM3)

- Reinforcement: Polyester anti-torsion braid

- Outer Sheath: PCP(5GM5)

- Marking: TSKCGEWOEU (number of cores)x(cross-section) (rated voltage)

LV Round EPR/PUR Reeling Cable-(NSHTOEU)

- Voltage: 0.6/1kV

- Conductor: Tinned copper flexible class 5

- Insulation: EPR(3GI3)

- Core identification: Up to 5 cores, From 6 cores: black with white numbers

- Core arrangement: Central filler, plastic or textile, if necessary covered with rubber.

- Inner Sheath: EPR rubber (5GM3)

- Reinforcement: Wide-meshed polyester braid, embedded in the sheath

- Outer Sheath: PCP / PUR (5GM5)

- Marking: NSHTOEU-J (number of cores) x (cross-section)

- Application: Flexible low-voltage reeling cable for application under medium mechanical stresses.

- 6/10kV Flat Reeling Cable Parameter

- 8.7/15kV Reeling Cable with Fiber Opitc Parameter

- 0.6/1kV Round Reeling Cable Parmater

| cores x cross section | Conductor diameter max. mm | Min.Height mm | Max.Height mm | Min.Width mm | Max.Width mm | Bending radius free moving min. mm | Weight (ca.) kg/km | Permissible tensile force max. N |

| 3×25+3×25/3E | 6.9 | 25 | 27.5 | 66.7 | 69.7 | 413 | 2860 | 1125 |

| 3×35+3×25/3E | 8.3 | 25.5 | 28.5 | 68.2 | 72.2 | 428 | 3260 | 1575 |

| 4×35+4×25/4E | 8.3 | 25.5 | 28.5 | 86.7 | 91.7 | 428 | 4110 | 2100 |

| 3×50+3×25/3E | 9.8 | 28.1 | 31.1 | 74.6 | 78.6 | 467 | 4030 | 2250 |

| 3×70+3×35/3E | 11.4 | 29.7 | 32.7 | 79.2 | 83.2 | 491 | 4850 | 3150 |

| 4×70+4×35/4E | 11.4 | 29.5 | 32.5 | 100.9 | 105.9 | 488 | 6240 | 4200 |

| 3×95+3×50/3E | 13.3 | 31.7 | 34.7 | 84.7 | 89.7 | 521 | 5920 | 4275 |

| 3×120+3×70/3E | 15.1 | 35.1 | 38.1 | 92.9 | 97.9 | 572 | 7420 | 5400 |

| Number of cores x cross section | Conductor diameter max. mm | Outer diameter min. mm | Outer diameter max. mm | Bending radius free moving min. mm | Weight (ca.) kg/km | Conductor resis- tance at 20°C max. |

| 3×25 + 2×25/2 +1x(12G62,5) | 6.2 | 42 | 45 | 450 | 2700 | 0.78 |

| 3×35 + 2×25/2 +1x(12G62,5) | 7.7 | 45 | 49 | 490 | 2960 | 0.55 |

| 3×50 + 2×25/2 +1x(12G62,5) | 9.3 | 50 | 54 | 540 | 3960 | 0.39 |

| 3×70 + 2×35/2 +1x(12G62,5) | 11.5 | 53 | 57 | 570 | 4760 | 0.27 |

| 3×95 + 2×50/2 +1x(12G62,5) | 12.8 | 58 | 62 | 620 | 5760 | 0.21 |

| 3×120 + 2×70/2 +1x(12G62,5) | 14.9 | 64 | 68 | 680 | 7265 | 0.16 |

| 3×150 + 2×70/2 +1x(12G62,5) | 16.5 | 68 | 72 | 720 | 8500 | 0.13 |

| 3×185 + 2×95/2 +1x(12G62,5) | 18.5 | 72 | 77 | 770 | 9900 | 0.11 |

| Number of cores x cross section | Conductor diameter max. mm | Outer diameter min. mm | Outer diameter max. mm | Bending radius free moving min. mm | Weight (ca.) kg/km | Currentcarrying capacity (1) |

| NSHTOEU-J Control cables | ||||||

| 7×1,5 | 1.5 | 16.2 | 17.5 | 105 | 380 | 23 |

| 12×1,5 | 1.5 | 20 | 21.4 | 128 | 550 | 23 |

| 18×1,5 | 1.5 | 22.4 | 23.8 | 143 | 730 | 23 |

| 24×1,5 | 1.5 | 25.4 | 27 | 162 | 950 | 23 |

| 30×1,5 | 1.5 | 27.8 | 29.4 | 176 | 1140 | 23 |

| 7×2,5 | 2 | 18.5 | 19.7 | 118 | 510 | 30 |

| 12×2,5 | 2 | 22.7 | 24 | 145 | 740 | 30 |

| 18×2,5 | 2 | 25.8 | 27.4 | 164 | 1020 | 30 |

| 24×2,5 | 2 | 30.1 | 32.1 | 193 | 1410 | 30 |

| NSHTOEU-J power cables, three core design | ||||||

| 3×50+3×25/3 | 9.6 | 41 | 45 | 270 | 2850 | 202 |

| 3×70+3×35/3 | 11.1 | 43 | 47 | 282 | 3860 | 250 |

| 3×95+3×50/3 | 12.6 | 48 | 52 | 312 | 4720 | 301 |

| 3×120+3×70/3 | 13.7 | 50.5 | 55.5 | 333 | 5820 | 352 |

| 3×150+3×70/3 | 16 | 57 | 62 | 372 | 6535 | 404 |

| 3×185+3×95/3 | 17.7 | 63 | 68 | 408 | 8890 | 461 |

| 3×240+3×95/3 | 20.2 | 71 | 76 | 456 | 12040 | 540 |

LV Flat EPR/CR Rubber Festoon Cable- NGFLGOEU-J

- Voltage: 300/500V(600V)

- Conductor: Eletrolytic copper, not tinned – up25mm2 Class6; -above35mm class5

- Insulation: EPR(3GI3)

- Individual screen: Braid screen made of tinned copper wires

- Core identification: Up to 5 cores black, blue, brown, grey , From 6 cores: black with white numbers

- Core arrangement: Parallel, for more than 12 cores: parallel bundles

- Reinforcement: Wide-meshed polyester braid, embedded in the sheath

- Outer Sheath: CR (5GM5)

- Marking: NSHTOEU-J (number of cores) x (cross-section)

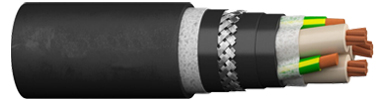

LV Round Screen Screen Festoon Cable – (N)GRDGCGOEU-J

- Voltage: 0.6/1kV

- Conductor: copper, class5

- Insulation: EPR(3GI3)

- Core identification: Light colored insulation with numbers printed in black for power and control cables, earth conductor green/ yellow

- Core arrangement: Up to 10mm²: 4-core design; from 16mm² on: three main conductors, earth conductor splitted into three parts and placed into the interstices

- Inner Sheath: EPR(Black)

- Screen: Braid screen made of tinned copper wires

- Outer Sheath: PCP (5GM3)

- Marking: NSHTOEU-J (number of cores) x (cross-section)

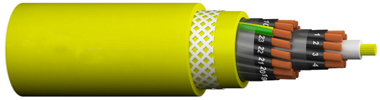

LV Festoon Cable for Energy Chain-(N) GRDGCGOEU

- Voltage: 0.6/1kV

- Conductor: Bare electrolytic copper, finely stranded, class 5

- Insulation: EPR(3GI3), Alternative for control cables: ETFE

- Core identification: Light colored insulation with numbers printed in black for power and control cables, earth conductor green/ yellow

- Core arrangement: Up to 10mm²: 4-core design; from 16mm² : 3-energy cores and splitted earth conductor into three parts.

- Screen: Braid screen made of tinned copper wires

- Inner Sheath: EPR(GM1B) Black

- Outer Sheath: EVA

- Marking: (N)GRDGOEU (number of cores)x(cross section)

- 0.6/1kV Basket Spreader Cable Parameter

- 0.6/1kV Round Screen Festoon Cable Parameter

- 0.6/1kV Chain Reeling Cable Parmater

| Number of cores x cross section | Conductor diameter max. mm | Min.Height mm | Max.Height mm | Min.Width mm | Max.Width mm | Bending radius free moving min. mm | Weight (ca.) kg/km | Permissible tensile force max. N |

| NGFLGOEU-J control cables | ||||||||

| 10×1,5 | 1.5 | 6.2 | 6.7 | 35.5 | 37 | 20 | 440 | 225 |

| 12×1,5 | 1.5 | 6.3 | 6.8 | 42 | 43.5 | 20 | 530 | 270 |

| 24×1,5 | 1.5 | 11.5 | 12.3 | 51 | 53.2 | 62 | 1040 | 540 |

| 42×1,5 | 1.5 | 15.1 | 16.1 | 70.2 | 72.3 | 81 | 1920 | 945 |

| 4×2,5 | 2 | 6.8 | 7.3 | 18.5 | 19.5 | 22 | 260 | 150 |

| 5×2,5 | 2 | 6.6 | 7.4 | 22.9 | 24.6 | 22 | 320 | 188 |

| 7×2,5 | 2 | 6.8 | 7.4 | 31 | 32.8 | 22 | 440 | 263 |

| 10×2,5 | 2 | 7.4 | 8 | 43 | 45.3 | 24 | 660 | 375 |

| 12×2,5 | 2 | 7.4 | 8 | 50.6 | 53.5 | 24 | 780 | 450 |

| NGFLGOEU-J power cables | ||||||||

| 4×16 | 5.6 | 12.1 | 12.9 | 36 | 37.5 | 65 | 1060 | 960 |

| 4×25 | 6.6 | 13.6 | 14.4 | 41.9 | 43.4 | 72 | 1500 | 1500 |

| 4×35 | 8.1 | 14.8 | 16.7 | 47 | 49.9 | 84 | 2040 | 2100 |

| 5×4 | 2.8 | 8.5 | 9 | 28.9 | 31.2 | 36 | 510 | 300 |

| 5×6 | 3.5 | 9.1 | 9.6 | 31.8 | 34.1 | 38 | 640 | 450 |

| 5×10 | 4.5 | 10.5 | 11.3 | 39.2 | 41.6 | 45 | 960 | 750 |

| 5×16 | 5.6 | 12.2 | 12.7 | 45.1 | 47.6 | 64 | 1360 | 1200 |

| Number of cores x cross section | Conductor diameter max. mm | Outer diameter min. mm | Outer diameter max. mm | Bending radius min. mm | Weight (ca.) kg/km | Nom.operating capaci- tance µF/km | Inductance nom. mH/ km | Current carrying capacity for install. |

| (N)GRDGCGOEU- J screened power cables | ||||||||

| 4×2,5 | 2 | 13 | 15 | 75 | 340 | 0.17 | 0.58 | 32 |

| 4×4 | 2.5 | 14.8 | 17.8 | 89 | 480 | 0.18 | 0.55 | 43 |

| 4×6 | 3 | 16.2 | 19.2 | 96 | 640 | 0.19 | 0.53 | 56 |

| 4×10 | 4 | 19.6 | 22.6 | 113 | 890 | 0.23 | 0.51 | 78 |

| 3×16+3×2,5 | 5.7 | 22.4 | 25.4 | 127 | 1150 | 0.225 | 0.48 | 104 |

| 3×25+3×4 | 6.8 | 25.4 | 28.4 | 142 | 1590 | 0.275 | 0.45 | 138 |

| 3×35+3×6 | 8.1 | 29.3 | 32.3 | 162 | 2160 | 0.325 | 0.43 | 170 |

| 3×50+3×10 | 9.6 | 35.4 | 38.4 | 192 | 3060 | 0.4 | 0.41 | 212 |

| 3×70+3×10 | 11.5 | 40.8 | 43.8 | 219 | 3960 | 0.475 | 0.39 | 263 |

| 3×95+3×16 | 12.9 | 43.4 | 46.4 | 232 | 4840 | 0.6 | 0.375 | 316 |

| 3×120+3×16 | 14.6 | 47.8 | 50.8 | 254 | 5910 | 0.7 | 0.36 | 370 |

| Number of cores x cross section | Conductor diameter max. mm | Outer diameter min. mm | Outer diameter max. mm | Bending radius min. mm | Weight (ca.) kg/km | Permissible tensile force max. N | Conductor resis- tance at 20°C max. |

| (N)GRDGOEU-J multicore power cables | |||||||

| 4×4 | 2.9 | 12.7 | 14.7 | 74 | 320 | 240 | 4.95 |

| 4×6 | 3.6 | 14.2 | 16.2 | 81 | 430 | 360 | 3.3 |

| 4×10 | 4.6 | 16.7 | 18.7 | 94 | 670 | 600 | 1.91 |

| 4×16 | 5.9 | 21.2 | 23.2 | 116 | 1020 | 960 | 1.21 |

| 4×25 | 7.2 | 26.5 | 29.5 | 148 | 1600 | 1500 | 0.78 |

| 3×35+3×16/3 | 8.1 | 26.4 | 29.4 | 147 | 1770 | 1570 | 0.55 |

| 3×50+3×25/3 | 10 | 31.5 | 34.5 | 173 | 2560 | 2250 | 0.39 |

| 3×70+3×35/3 | 11.9 | 37.6 | 40.6 | 203 | 3550 | 3150 | 0.27 |

| (N)GRDGCGOEU- J multicore power cables, overall screened | |||||||

| 4×2,5C | 1.9 | 11.2 | 13.2 | 66 | 310 | 150 | 7.98 |

| 4x4C | 2.9 | 15.2 | 17.2 | 86 | 490 | 240 | 4.95 |

| 4x6C | 3.6 | 17 | 19 | 95 | 650 | 360 | 3.3 |

| 4x10C | 4.6 | 19.2 | 21.2 | 106 | 870 | 600 | 1.91 |

| 3×16+3×2,5C | 5.9 | 20.3 | 22.3 | 112 | 1050 | 720 | 1.21 |

| 3×25+3x4C | 7.2 | 25.7 | 28.7 | 144 | 1610 | 1120 | 0.78 |

| 3×35+3x6C | 8.1 | 28.4 | 31.4 | 157 | 2140 | 1570 | 0.55 |

| 3×50+3×25/3 | 10 | 34.9 | 37.9 | 190 | 3080 | 2250 | 0.39 |

| 3×70+3×35/3 | 11.8 | 39.8 | 42.8 | 214 | 4090 | 3150 | 0.27 |

LV Spreader EPR/PUR Cable for Basket-3GSLTOE-J

- Voltage: 0.6/1kV

- Conductor: Bare electrolytic copper, finely stranded, class 5

- Insulation: EPR(3GI3), Alternative for control cables: ETFE

- Core identification: Optimal identification as a result of light colored insulation with numbers printed in black; protective earth conductor green/yellow

- Individual Screen: Braid screen made of tinned copper wires

- Core arrangement: Core assembly: cores laid-up into bundles;

- Bundle assembly: bundles laid-up around the central support element.

- Outer Sheath: PUR (Black)

- Marking: 3GSLTOE-J (number of cores) x (cross-section)

LV Spreader EPR/PCP Cable for Vertical Reeling

- Voltage: 0.6/1kV

- Conductor: Bare electrolytic copper, finely stranded, class 5

- Insulation: ETFE

- Core identification: Best identification as a result of black colored insulation with light printed numbers, earth conductor green-yellow

- Individual Screen: Braid screen made of tinned copper wires

- Support element: Central aramide support element to increase the loading capability.

- Inner sheath: PCP rubber

- Core arrangement: Laid-up in a maximum of 3 layers

- Outer Sheath: PCP rubber

- Marking: (N)SHTOEU-J/-O (number of cores)x(cross-section)

LV Lift Trailing PUR-HF Cable for Vertical Reeling

- Voltage: 0.6/1kV

- Conductor: Class 5 or Class 6 flexible stranded Copper

- Cores: 3core, 4 core, 5core

- Cross-sectional area: 10mm2~35mm2

- Insulation: XLPE (Cross-linked Polyethylene)

- Inner Sheath: PUR-HF (Polyurethane Halogen Free Flame Retardant)

- Braid: Anti-twist aramid yarns

- Outer Sheath: PUR-HF (Polyurethane Halogen Free Flame Retardant)

- Application: For use as vertical reeling cable under high mechanical stresses,torsion, tension and torque.

- 0.6/1kV Basket Spreader Cable Parameter

- 0.6/1kV Spreader Vertical Reeling Cable Parameter

- 0.6/1kV Lift Vertical Reeling Cable Parmater

| Number of cores x cross section | Conductor diameter max. mm | Outer diameter min. mm | Outer diameter max. mm | Bending radius free moving min. mm | Weight(ca.) kg/km | Conductor resis- tance at 20°C max. |

| 3GSLTOE-J control cables | ||||||

| 24×2,5 | 2 | 29.1 | 32.1 | 161 | 1780 | 7.98 |

| 30×2,5 | 2 | 31.1 | 34.1 | 171 | 2260 | 7.98 |

| 36×2,5 | 2 | 34.5 | 37.5 | 188 | 2780 | 7.98 |

| 42×2,5 | 2 | 36.8 | 39.8 | 199 | 3490 | 7.98 |

| 48×2,5 | 2 | 41.3 | 44.3 | 222 | 4040 | 7.98 |

| 24×3,5 | 2.4 | 32 | 35 | 175 | 2350 | 5.55 |

| 30×3,5 | 2.4 | 34.3 | 37.3 | 187 | 2970 | 5.55 |

| 36×3,5 | 2.4 | 37.9 | 40.9 | 205 | 3750 | 5.55 |

| 42×3,5 | 2.4 | 42.4 | 45.4 | 227 | 4510 | 5.55 |

| 3GSLTOE-J control cables with bus element | ||||||

| 24×2,5+1x(2×1)C | 2 | 31.1 | 34.1 | 171 | 2200 | 7.98 |

| 24×2,5+4x(2×1)C | 2 | 41.2 | 44.2 | 221 | 3600 | 7.98 |

| 36×2,5+2x(2×1)C | 2 | 41.3 | 44.3 | 222 | 3830 | 7.98 |

| 42×2,5+2x(2×1)C | 2 | 43.5 | 46.5 | 233 | 3600 | 7.98 |

| Number of cores x cross section | Conductor diameter max. mm | Outer diameter min. mm | Outer diameter max. mm | Bending radius free moving min. mm | Weight (ca.) kg/km | Permissible tensile force max. N |

| (N)SHTOEU-J control cables | ||||||

| 12×2,5 | 2 | 22 | 25 | 125 | 870 | 2700 |

| 24×2,5 | 2 | 26.2 | 29.2 | 146 | 1300 | 3600 |

| 30×2,5 | 2 | 29.4 | 32.4 | 162 | 1630 | 4100 |

| 44×2,5 | 2 | 34.1 | 37.1 | 186 | 2200 | 5100 |

| (N)SHTOEU-J control cables with fiber optical | ||||||

| 22×2,5+4x(3G50) | 2 | 28.2 | 31.2 | 156 | 1390 | 3450 |

| 22×2,5+2x(3G62,5) | 2 | 26.2 | 29.2 | 146 | 1260 | 3450 |

| 24×2,5+6x(2G62,5) | 2 | 29.4 | 32.4 | 162 | 1510 | 3600 |

| 28×2,5+2x(3G62,5) | 2 | 29.4 | 32.4 | 162 | 1590 | 3900 |

| 28×2,5+2x(3G50) | 2 | 29.4 | 32.4 | 162 | 1590 | 3900 |

| 36×2,5+8x(1G62,5) | 2 | 34.1 | 37.1 | 186 | 2050 | 4500 |

| 38×2,5+6x(2G62,5) | 2 | 34.1 | 37.1 | 186 | 2090 | 4650 |

| 41×2,5+3x(2G62,5) | 2 | 34.1 | 37.1 | 186 | 2150 | 4875 |

| 41×2,5+3x(2G50) | 2 | 34.1 | 37.1 | 186 | 2160 | 4875 |

| NO. OF CORES | NOMINAL CROSS SECTIONAL AREA | NOMINAL OVERALL DIAMETER | NOMINAL WEIGHT | |

| mm | ||||

| mm2 | Minimum | Maximum | kg/km | |

| 4 | 10 | 17.4 | 18.9 | 610 |

| 4 | 16 | 20 | 22.1 | 852 |

| 4 | 25 | 22.9 | 25.3 | 1228 |

| 4 | 35 | 28.5 | 30.2 | 1760 |

| 5 | 10 | 18.7 | 20.5 | 724 |

| 5 | 16 | 21.7 | 24.2 | 1030 |

| 5 | 25 | 30 | 36 | 2570 |

Crane cable application environment

Reeling Operation System

Festoon Operation System

Basket Operation System

Chain Operation System

Trailing Operation System