Application

The medium voltage cable is used for ground, within and outside facilities, outdoors, in cable canals, in dry areas, or water.

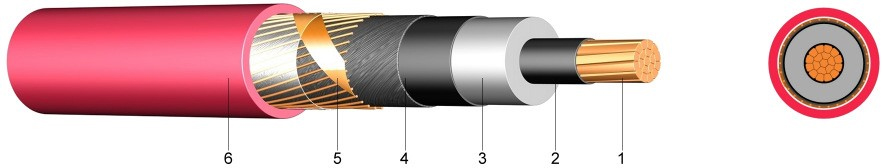

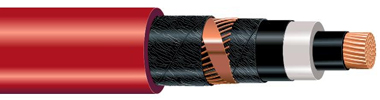

Construction

- 1 ….. Stranded (RM) bare copper or aluminum wires

- 2 …..Inner layer of semi-conducting material

- 3 ….. Core insulation of cross-linked polyethylene

- 4 ….. Outer layer of semi-conducting material

- 5 ….. Screen of copper wires

- 6 ….. PVC red outer sheath or PE black outer sheath

Technical Data

- Test Voltage: 6/10kV 12/20kV 18/30kV

- Temperature range:

- 1. in motion: – 20°C till +90°C

- 2. fixed: -20°C till +90c

- Operating temperature: short circuit: 250°C

- Bending radius: min.x diameter 15

- Short circuit time: max. [sec] 5

Standards

- DIN VDE 0276-620

- HD 620 S1: 1995

- DIN EN 60228 class 1 and 2 (construction)

- Application: To be laid directly in ground, outdoors, indoors and in cable ducts.

AL/Cu Conductor XLPE Insulation PVC Sheath N2XSY/NA2XSY Screen Cable

- Voltage: 6/10kV 12/20kV 18/30kV

- Core: Single Core

- Conductor: (RM) Bare Copper

- Section-area: 35~50mm

- Insulation: XLPE

- Screen: copper wire

- Outer Sheath: PVC Red

AL/Cu Conductor XLPE Insulation PE Sheath N2XS2Y/NA2XS2Y Screen Cable

- Voltage: 6/10kV 12/20kV 18/30kV

- Core: Single Core

- Conductor: (RM) Bare Copper

- Section-area: 35~50mm

- Insulation: XLPE

- Screen: copper wire

- Outer Sheath: PE; Blacke.

Al/Cu XLPE/PE Sheath N2XS(F,FL)2Y NAXS(F,FL) Waterproof Cable

- Voltage: 6/10kV 12/20kV 18/30kV

- Core: Single Core

- Conductor: (RM) Aluminum wire

- Section-area: 35~50mm

- Insulation: XLPE

- Screen: copper wire

- Outer Sheath: PVC; Red.

- 6/10kV 12/20kV18/30kV N2XSY Cable Parameter

- 6/10kV 12/20kV18/30kV N2XS2Y Cable Parameter

| Number of cores | Copper figure | Overall diameter | Overall diameter max. value | Weight appr. | Current carrying capacity ground | Current carrying capacity air |

| mm² | kg/km | appr. mm | appr. mm | kg / km | A* | A* |

| 6 / 10 kV | ||||||

| 1 x 35 RM/16 | 540 | 23 | 28 | 900 | 187 | 197 |

| 1 x 50 RM/16 | 690 | 24 | 29 | 1.05 | 220 | 236 |

| 1 x 70 RM/16 | 890 | 26 | 31 | 1.3 | 268 | 294 |

| 1 x 95 RM/16 | 1.14 | 27 | 32 | 1.6 | 320 | 358 |

| 1 x 120 RM/16 | 1.39 | 29 | 34 | 1.85 | 363 | 413 |

| 1 x 150 RM/25 | 1.795 | 30 | 35 | 2.2 | 405 | 468 |

| 1 x 185 RM/25 | 2.145 | 32 | 37 | 2.6 | 456 | 535 |

| 1 x 240 RM/25 | 2.695 | 34 | 39 | 3.15 | 526 | 631 |

| 1 x 300 RM/25 | 3.295 | 36 | 40 | 3.75 | 591 | 722 |

| 1 x 400 RM/35 | 4.41 | 40 | 45 | 4.65 | 662 | 827 |

| 1 x 500 RM/35 | 5.41 | 43 | 47 | 5.75 | 739 | 921 |

| 1 x 35 RM/16 | 540 | 27 | 32 | 1.1 | 189 | 200 |

| 12/ 20 kV | ||||||

| 1 x 50 RM/16 | 690 | 28 | 33 | 1.25 | 222 | 239 |

| 1 x 70 RM/16 | 890 | 30 | 35 | 1.45 | 271 | 297 |

| 1 x 95 RM/16 | 1.14 | 31 | 36 | 1.75 | 323 | 361 |

| 1 x 120 RM/16 | 1.39 | 33 | 38 | 2.05 | 367 | 416 |

| 1 x 150 RM/25 | 1.795 | 34 | 39 | 2.4 | 409 | 470 |

| 1 x 185 RM/25 | 2.145 | 36 | 41 | 2.8 | 461 | 538 |

| 1 x 240 RM/25 | 2.695 | 39 | 44 | 3.4 | 532 | 634 |

| 1 x 300 RM/25 | 3.295 | 41 | 46 | 4 | 599 | 724 |

| 1 x 400 RM/35 | 4.41 | 44 | 49 | 4.95 | 671 | 829 |

| 1 x 500 RM/35 | 5.41 | 47 | 52 | 6.05 | 754 | 953 |

| 18 / 30 kV | ||||||

| 1 x 50 RM/16 | 690 | 33 | 38 | 1.45 | 225 | 241 |

| 1 x 70 RM/16 | 890 | 35 | 40 | 1.7 | 274 | 299 |

| 1 x 95 RM/16 | 1.14 | 36 | 41 | 2.05 | 327 | 363 |

| 1 x 120 RM/16 | 1.39 | 38 | 43 | 2.3 | 371 | 418 |

| 1 x 150 RM/25 | 1.795 | 39 | 44 | 2.7 | 414 | 472 |

| 1 x 185 RM/25 | 2.145 | 41 | 46 | 3.1 | 466 | 539 |

| 1 x 240 RM/25 | 2.695 | 43 | 48 | 3.7 | 539 | 635 |

| 1 x 300 RM/25 | 3.295 | 46 | 51 | 4.35 | 606 | 725 |

| 1 x 400 RM/35 | 4.41 | 49 | 54 | 5.3 | 680 | 831 |

| 1 x 500 RM/35 | 5.41 | 52 | 57 | 6.45 | 765 | 953 |

| Number of cores | Copper figure | Overall diameter | Overall diameter max. value | Weight appr. | Current carrying capacity ground | Current carrying capacity air |

| mm² | kg/km | appr. mm | appr. mm | kg / km | A* | A* |

| 6 / 10 kV | ||||||

| 1 x 35 RM/16 | 540 | 23 | 28 | 820 | 187 | 197 |

| 1 x 50 RM/16 | 690 | 24 | 29 | 960 | 220 | 236 |

| 1 x 70 RM/16 | 890 | 26 | 31 | 1.15 | 269 | 292 |

| 1 x 95 RM/16 | 1.14 | 27 | 32 | 1.45 | 320 | 358 |

| 1 x 120 RM/16 | 1.39 | 29 | 34 | 1.7 | 363 | 413 |

| 1 x 150 RM/25 | 1.795 | 30 | 35 | 2 | 405 | 468 |

| 1 x 185 RM/25 | 2.145 | 32 | 37 | 2.35 | 456 | 535 |

| 1 x 240 RM/25 | 2.695 | 34 | 39 | 2.9 | 526 | 631 |

| 1 x 300 RM/25 | 3.295 | 36 | 41 | 3.55 | 591 | 722 |

| 1 x 400 RM/35 | 4.41 | 40 | 45 | 4.5 | 662 | 827 |

| 1 x 500 RM/35 | 5.41 | 43 | 48 | 5.55 | 744 | 949 |

| 12 / 20 kV | ||||||

| 1 x 35 RM/16 | 540 | 27 | 32 | 1 | 189 | 200 |

| 1 x 50 RM/16 | 690 | 28 | 33 | 1.15 | 222 | 239 |

| 1 x 70 RM/16 | 890 | 30 | 35 | 1.35 | 271 | 297 |

| 1 x 95 RM/16 | 1.14 | 31 | 36 | 1.6 | 323 | 361 |

| 1 x 120 RM/16 | 1.39 | 33 | 38 | 1.85 | 367 | 416 |

| 1 x 150 RM/25 | 1.795 | 34 | 39 | 2.25 | 409 | 470 |

| 1 x 185 RM/25 | 2.145 | 36 | 41 | 2.6 | 461 | 538 |

| 1 x 240 RM/25 | 2.695 | 39 | 44 | 3.15 | 532 | 634 |

| 1 x 300 RM/25 | 3.295 | 41 | 46 | 3.8 | 599 | 724 |

| 1 x 400 RM/35 | 4.41 | 44 | 49 | 4.75 | 671 | 829 |

| 1 x 500 RM/35 | 5.41 | 47 | 52 | 5.8 | 754 | 953 |

| 18 / 30 kV | ||||||

| 1 x 50 RM/16 | 690 | 33 | 38 | 1.35 | 225 | 241 |

| 1 x 70 RM/16 | 890 | 35 | 40 | 1.6 | 274 | 299 |

| 1 x 95 RM/16 | 1.14 | 36 | 41 | 1.9 | 327 | 363 |

| 1 x 120 RM/16 | 1.39 | 38 | 43 | 2.2 | 371 | 418 |

| 1 x 150 RM/25 | 1.795 | 39 | 44 | 2.55 | 414 | 472 |

| 1 x 185 RM/25 | 2.145 | 41 | 46 | 2.95 | 466 | 539 |

| 1 x 240 RM/25 | 2.695 | 43 | 48 | 3.5 | 539 | 635 |

| 1 x 300 RM/25 | 3.295 | 46 | 51 | 4.15 | 606 | 725 |

| 1 x 400 RM/35 | 4.41 | 49 | 54 | 5.15 | 680 | 831 |

| 1 x 500 RM/35 | 5.41 | 52 | 57 | 6.2 | 765 | 953 |